Politubes supplies a wide range of process release films and liners for rubber and elastomer blends designed to be used in the processing of rubber compounds and to roll up and separate coils of rubber waiting to be vulcanized.

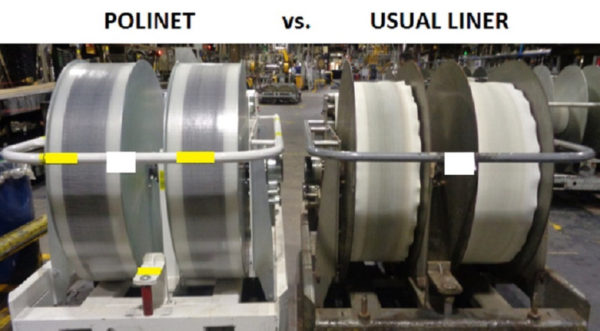

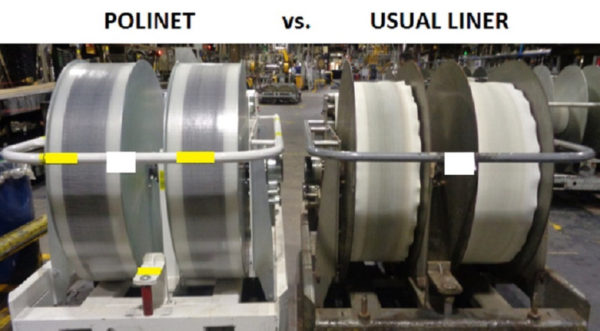

Always attentive to our customers’ needs, we have introduced a new POLINET service release liner with very high tear resistance and with excellent mechanical qualities and release properties for those processes that require a stiffer film.

This new release liner is a stiff polyester-based multilayer film that is reinforced internally with a high tear resistance mesh; the film is then embossed in a second step to increase its release properties.

This separation service liner is used by tire (tyre) producers as inner liner, side wall and rubber compounds separator.

This release film drastically reduces tire production costs and improves tire quality. Polinet is chosen by the major tire manufacturers as it offers:

- Excellent release qualities of the tire rubber thanks to its special embossed surface, preventing deformations

- Optimal preservation of shapes and surfaces, without creases or deformation of the rubber

- Reduction in machine downtime costs and related waste; this translates into an increase in productivity and a reduction of hidden production costs

- High mechanical strength and tear resistance.

- Superior ability to preserve the fresh rubber sheet.

- Reduction in costs compared to products used for the same purpose, as it can be re-used 20-25 times more than conventional products, also due to the fact that it is easy to repair.

- Absence of any polluting substances, fraying or bagging

- Product that is environmentally friendly and has reduced disposal costs

Politubes technical office is available to listen to your needs and offer you tailor-made innovative solutions.

RELATED APPLICATIONS