KAPTON® NOMEX® 464 – 864 DUPONT INSULATING TUBES, TUBING, SLEEVE & ULTRASONIC WELDED INSULATOR CAPS

THERMAL CLASS H-C

Kapton® polyimide spiral tubing and ultrasonic welded caps manufactured by Politubes are used for the most demanding applications where extraordinary thermal stability, dielectric strength chemical resistance are required.

The spiraling technique consists in coupling a series of adhesive-coated strips, winding them around a mandrel, obtaining a tubular whose electrical, thermal and mechanical characteristics are the sum of the ones of each layer.

These custom designed Kapton® components can be supplied as tubes or ultrasonic welded insulation caps in order to guarantee the hermetic closure on one side.

DuPont™ Kapton® HN general-purpose film has been used successfully in applications at temperatures as low as -269°C and as high as + 400°C. Kapton® polyimide is a flame resistant material.

When the highest performance in terms of dielectric strength and heat dissipation, thermal conductivity is required we recommend DuPont™ Kapton® MT polyimide film that is a homogeneous film possessing 3x the thermal conductivity and cut through strength of standard Kapton® HN. Its thermal conductivity properties make it ideal for use in electronic and automotive applications such stator slot liner insulator in 800V motors.

Kapton® tubes and caps can be supplied:

- Made 100 % of Kapton® when it is required to stand to temperatures up to 280° C

- In combination with Nomex® 410 – 464 – 864 DuPont when it is required to stand to temperature up to 220°C and guarantee excellent impregnation properties as well

Politubes adhesives, carefully selected during our forty years of experience, comply with all REACH and RoHS most updated regulations. They are compatible with resins and chemicals in the end-use application and guarantee that the original thermal, dielectric, mechanical, chemical properties of the films used are fully maintained.

APPLICATIONS

Kapton® & Kapton® / Nomex® tubes & caps are mainly used for:

Kapton® & Kapton® / Nomex® tubes & caps are mainly used for:

- Stator slot liner insulation for copper hairpin in 400V & 800V motors

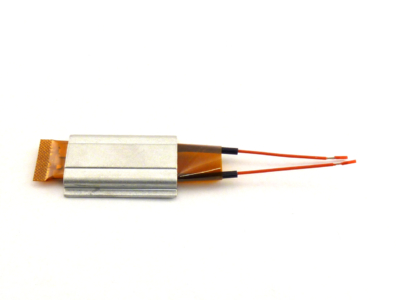

- Protection and insulation in anti-condensation heaters (RAC)

- Enclosure heaters & heaters

- Cartridge heaters

- Electric resistors

- PTC heating elements

- Soldering applications

- High temperature sheath

- Slot liner insulation

- Inverter-driven motors and generators

- Inverter transformers

- Electrical equipment used in high-altitude areas

- Motor lead terminals

- Wiring

Our Engineers are at your disposal to custom design and offer more technical specs for your specific application at orders@politubes.com – www.politubes.com – Phone +39-039-9054901 (Italy).

KAPTON® – KAPTON® / NOMEX® TUBES & ENDCAPS TECHNICAL SPECIFICATION

| Inside diameter | From 1.8 to 123 mm |

| Thickness | From 0.05 to 0.35 mm |

| Length | From 6 to 6000 mm – Tubes rewound in rolls can reach 1000 meters length |

| Types of insulation end caps available | Ultrasonic welded |

| Dielectric strength Kapton® HN 25 micron | 303 kV / mm – ASTM D 149 -91 |

| Dielectric strength Kapton® HN 50 micron | 240 kV / mm – ASTM D 149 -91 |

| Dielectric strength Nomex® 410 – 50 micron | 430 V/mil – ASTM D 149 |

| Dielectric strength Nomex® 410 – 80 micron | 550 V/mil – ASTM D 149 |

| Dielectric strength Nomex® 864 – 50 micron | 558 V/mil – ASTM D 149 |

| Dielectric strength Nomex® 864 – 80 micron | 635 V/mil – ASTM D 149 |

| Service temperature Kapton® tubes & caps | – 70 °C to +280 °C. |

| Service temperature Kapton® – Nomex® tubes & caps | – 70 °C to +220 °C. |

| Kapton® melting point | None – ASTM E-794-85 (1989) |

| Kapton® zero strength temperature | 815 °C – Hot Bar DuPont test. |

Kapton® UL certification is nr E39505. Nomex® UL certification is nr E34739. Politubes will provide specific tubes & caps technical data sheet accordingly with sizes requested. Kapton® is a DuPont Registered Trademark. Nomex® is a DuPont Registered Trademark.